Printing Charles Williams: a production tour!

During our family vacation in Michigan, I dragged the family on a side trip to visit the printing facility that actually produces the Charles Williams Library, my side project series of republishing collector’s hardback editions. I did a ton of research at the beginning of the project selecting this printer, but I’ve never actually visited the press!

They’re done at McNaughton and Gunn, an established printer who does a ton of books. Our little boutique runs are a drop in the bucket compared to their big clients, but they also do tiny projects: digital runs of a just a hundred copies. For our books, MG prints the endpapers and offset book blocks, binds the signatures together, and then sends the block to a separate vendor to do the clothbound hardback binding.

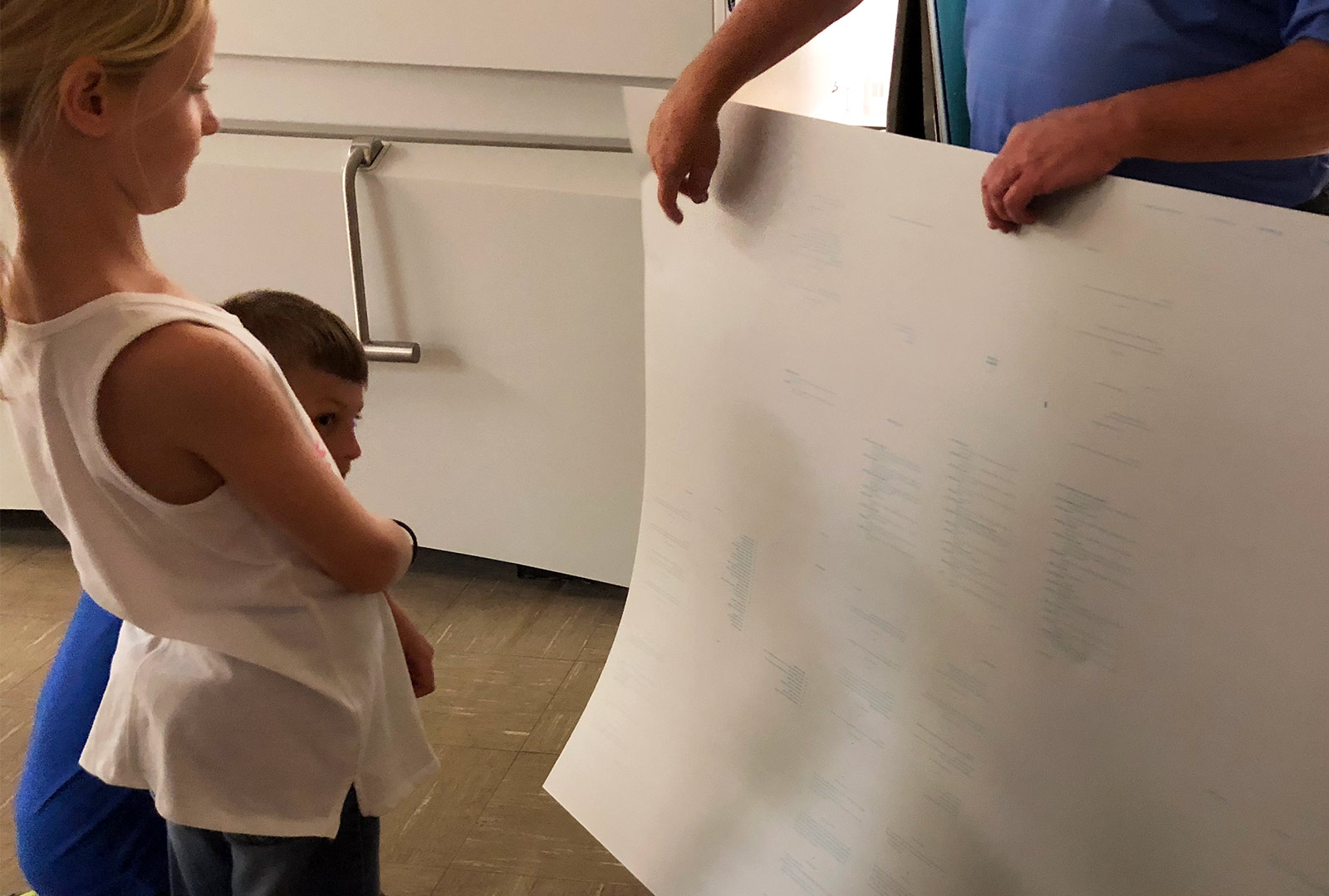

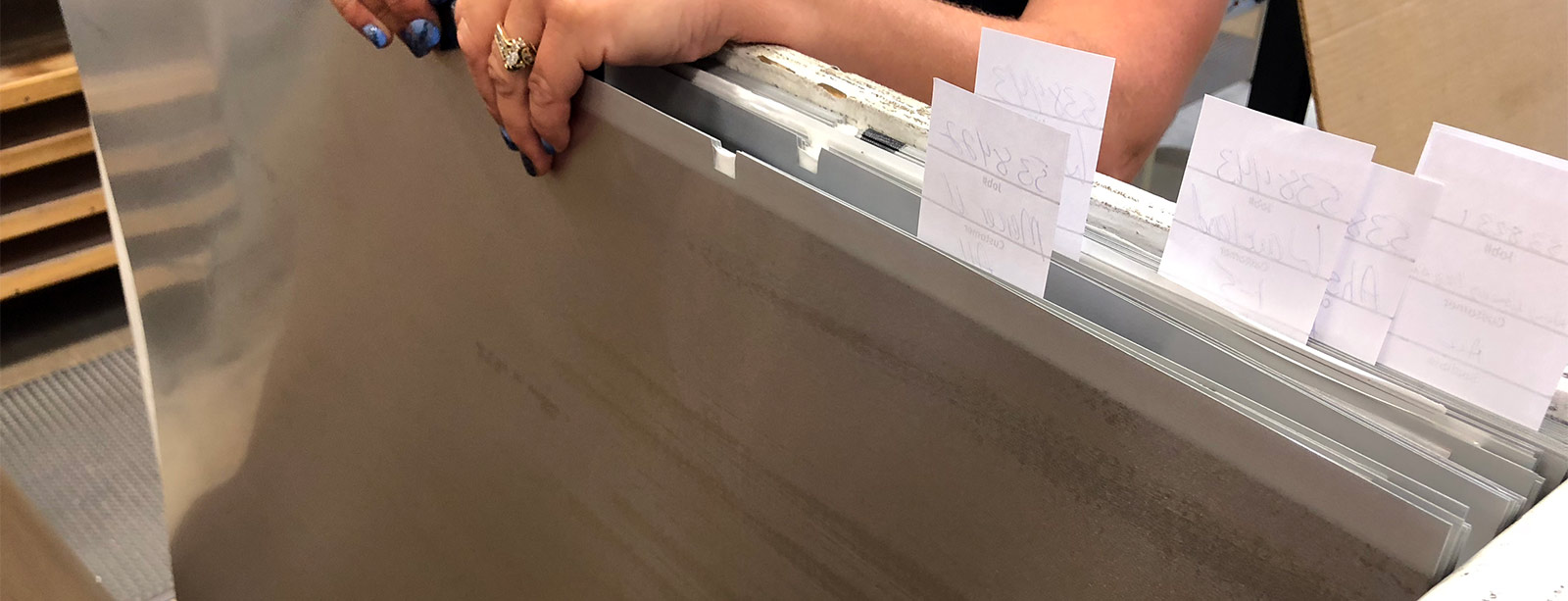

The process starts with a sheet of aluminum; these big sheets are fed into a big machine that creates a raised surface for the ink. For our books, a full 32-page signature fits onto one of these large spreads.

This giant machine looks like a supersized laser printer: clean aluminum goes in one side, the raised surface comes out the other.

The sheets are notched, a simple little shortcut to make sure the printing registers in the same place every time.

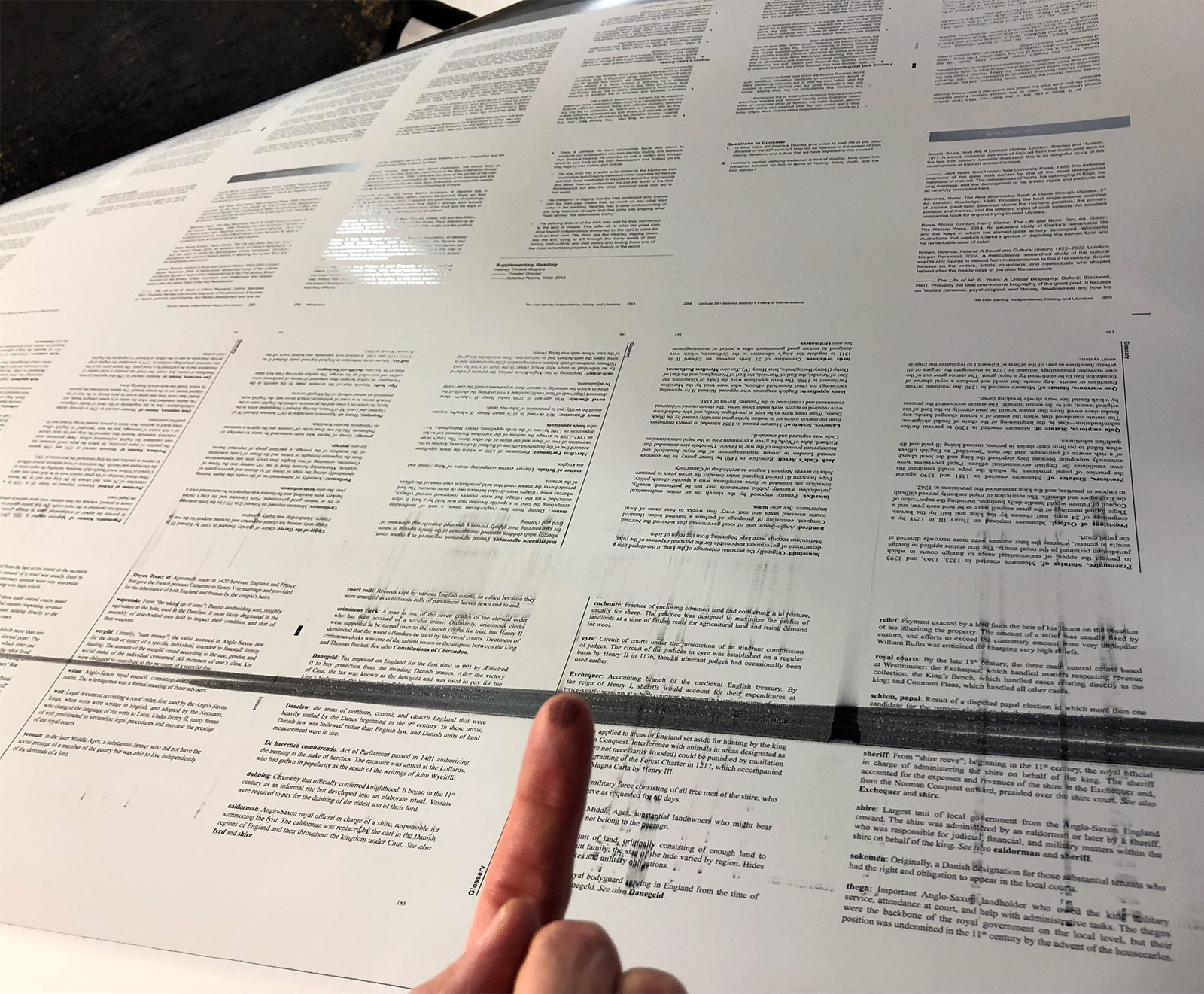

MG has a ton of different machines that do different page and signature sizes, based on paper intakes and print scales - but they all end up transferring ink from a roller to the aluminum sheet, then to on to a large sheet of paper. Here above is a sheet that’s been inked too much.

Most printing happens with a giant roll of paper that feeds into the press, but I particularly admired this machine, which takes a HUGE stack of paper and gingerly selects a single sheet to feed. Getting the configuration right to apply the correct amount of suction and pressure for each paper type must be really difficult. It’s maybe a bit hard to see, but that machine is using little suction cups to grab a single sheet of paper at a time.

While our books have their signatures sewn together, MG does a lot of perfect bound books - that’s when the folded part of the signatures are chopped or ground off, then a swath of hot glue is applied to the edge. Here’s an older machine running the full volume past the hot glue.

They also have a super impressive all-in-one machine, that takes the printed signatures and grinds the edge off, applies glue, dries the glue, trims the edges of the three cut sides, and then stacks the books neatly for packaging. Here’s a gif showing glued books coming out of one part of the machine, traveling up a big spiral and then down a conveyor towards trimming. The spiral exists just to give the glue time to cool!

Our Charles Williams books aren’t ‘perfect-bound’, of course - rather than glue ours use real thread to stitch the signatures together. The binding machines look like giant sewing machines, but still pretty modest compared to the scale of the place.

After that stage, our books are shipped off to a binding facility where the cloth bound covers are created, debossed, stamped and foiled, and attached with the endpapers. Maybe next time I’ll make time to visit there!

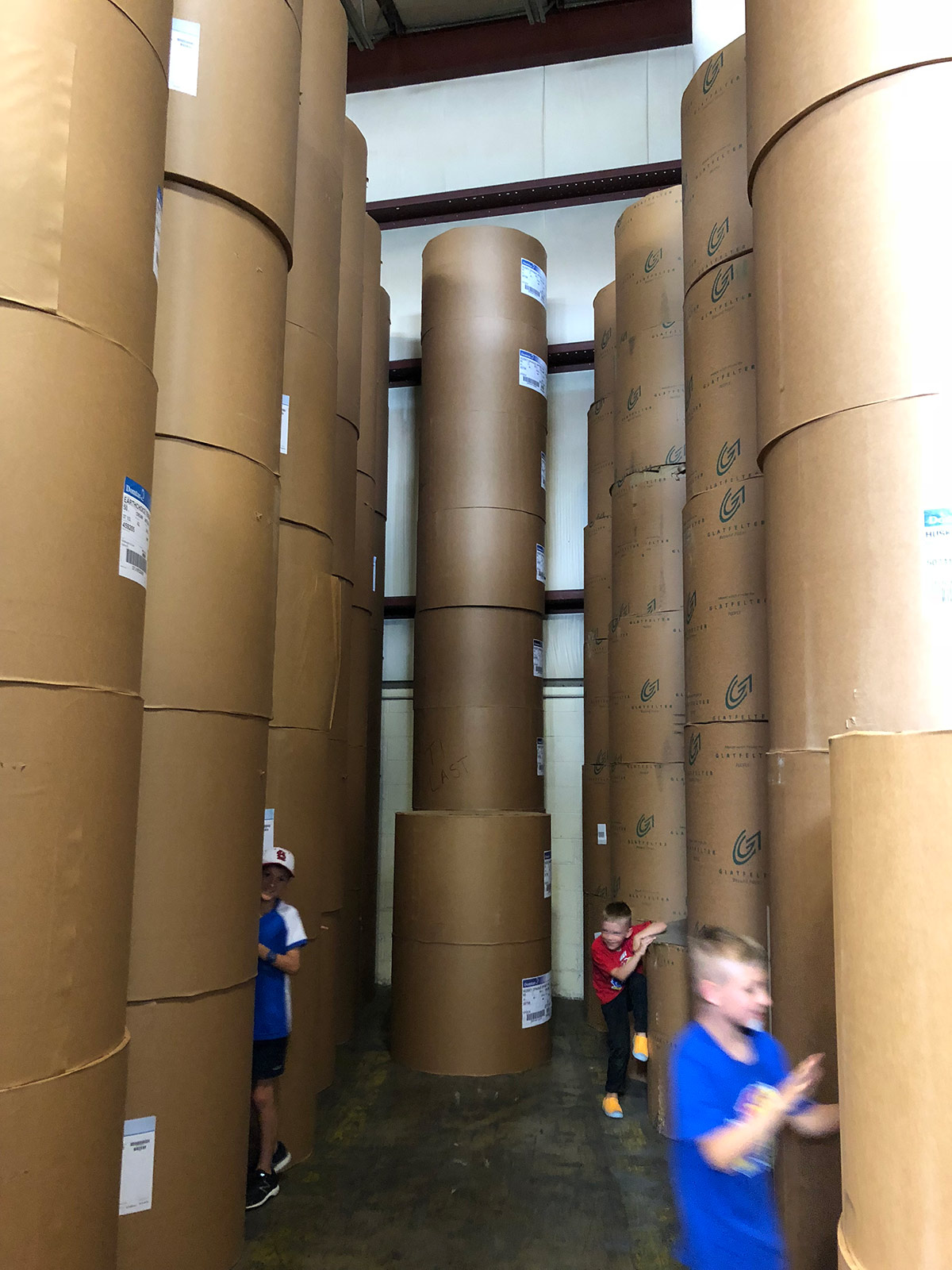

We also got to see the storage room where the HUGE rolls of paper are; here’s an image for scale below, but each of these rolls can weigh as much as my car. The warehouse had aisles and aisles of paper stacked five or six rolls high, probably close to a thousand rolls that size. The production manage said the’ll use up that much paper every few weeks!

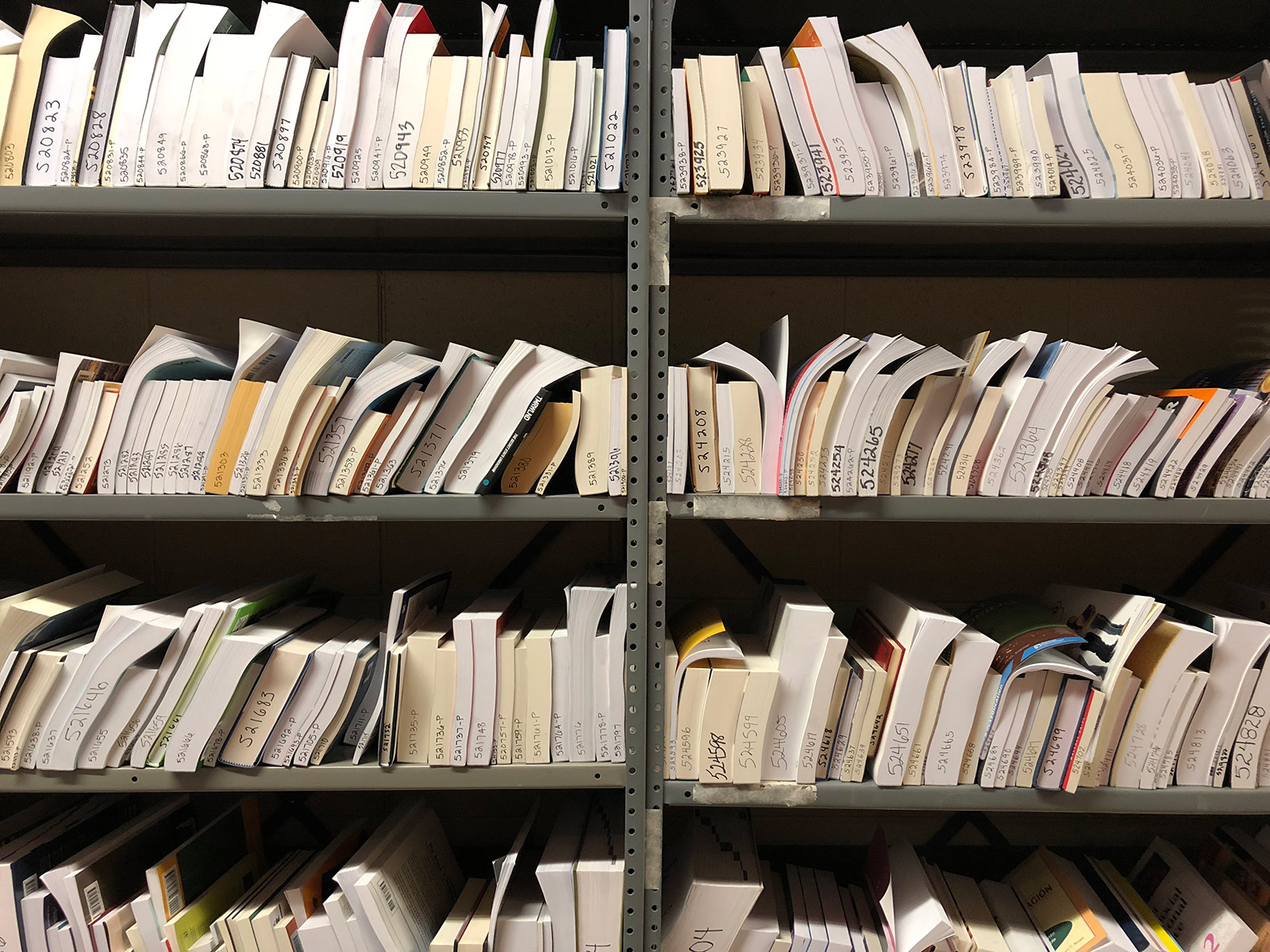

And at the very end, near the break room - a shelf of reference copies, so they can check on previous projects work. I appreciated this bit most, as we’re running a series of editions that are spread out over a few years of production!